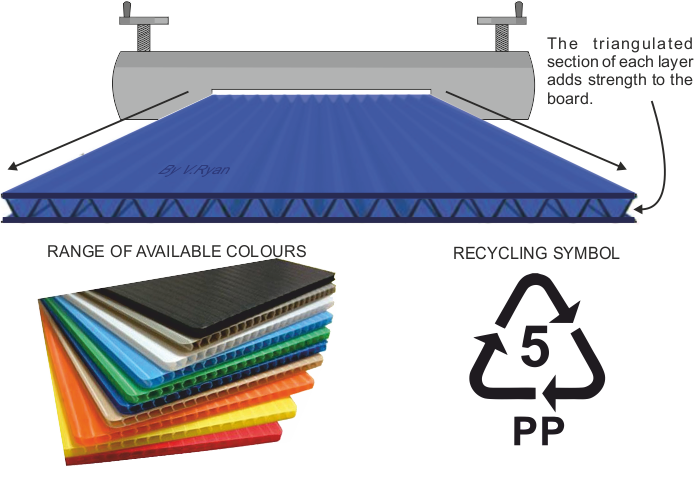

Correx is an extruded twin wall fluted corrugated polypropylene sheet and offers efficient solutions to a wide variety of applications.

Corrugated polypropylene sheet properties.

Corrugated plastic sheets are high impact twin wall plastic sheets that are made from polypropylene copolymer.

Polypropylene has a neutral ph and is resistant to many chemicals at normal temperatures but can be dosed with additives to provide a variety of other resistance such as uv anti static and fire resistance for example.

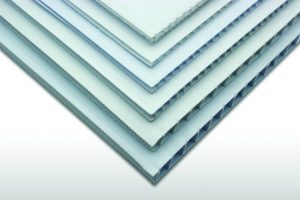

White twin wall sheet case of 8 twin wall profile extrusion made from polypropylene twin wall profile extrusion made from polypropylene or polyethylene.

Typical mechanical properties a edge crush resistance ecr and flat crush resistance fcr.

Pp sheet of straight flute and i beam rib.

Our polypropylene sheet has a smooth even surface for use in silk screen printing indoor and outdoor signs point of purchase displays and returnable packaging.

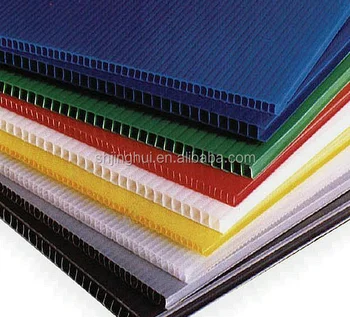

Corrugated plastic sheet is the future as it holds great versatility and quality.

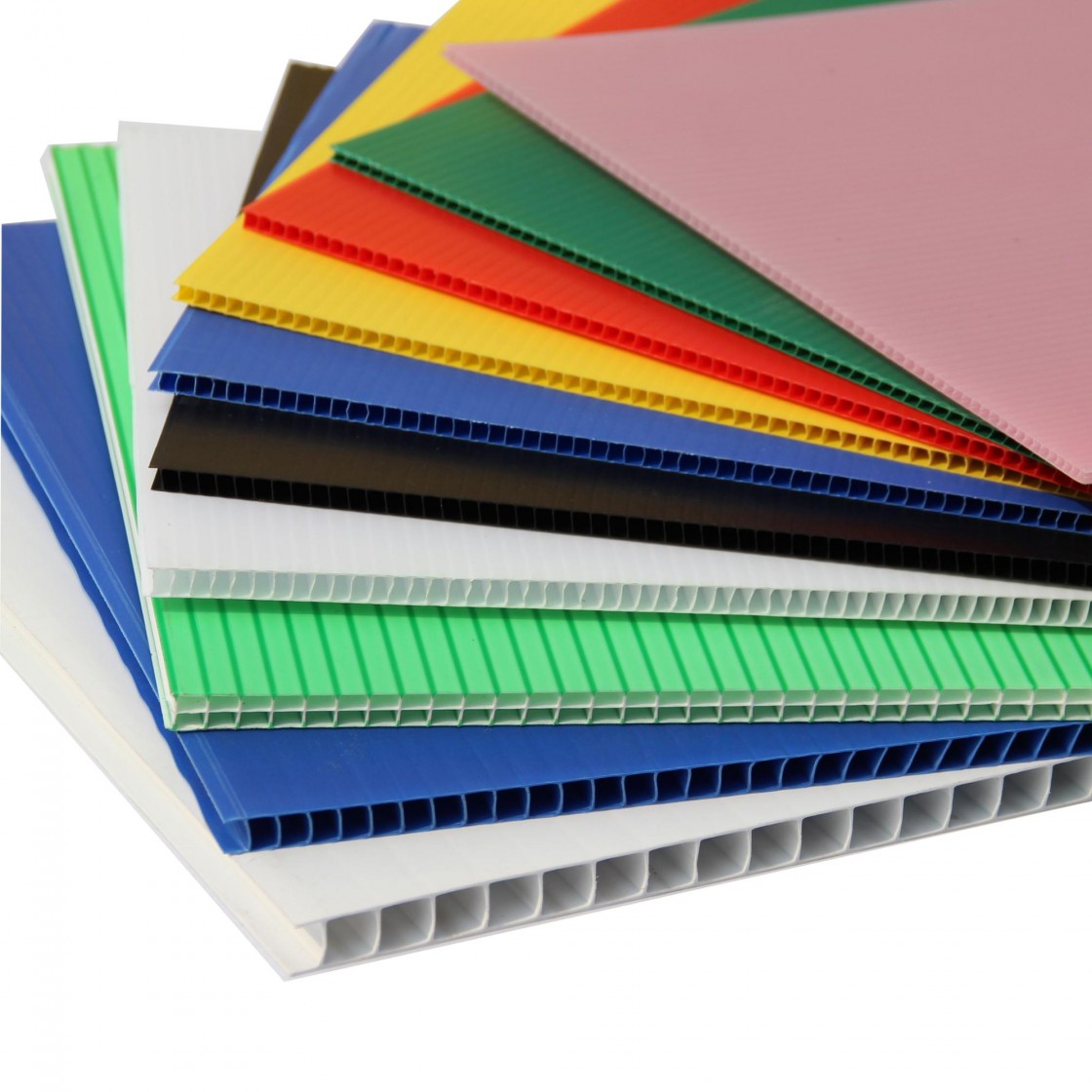

Due to its high strength and endurance a corrugated plastic sheet can be seen as the best alternative to wood and paper fabrications.

High density polyethylene corrugated plastic typical physical properties a thermal expansion coefficient astm d 696.

Corrugated plastic sheets are great for home use the manufacturing industry and the goods and services industry.

Fluted corrugated polypropylene pp sheet a polyolefin product is a lightweight material known for its versatility across many industries and applications.

It is favored by the industry for its lightweight structure and competitive pricing.

130oc d water vapor transmission rate wvtr at 23oc astm c 209.

Corrugated plastic or corriboard also known under the tradenames of cartonplast polyflute coroplast fluteplast intepro proplex correx twinplast corriflute or corflute refers to a wide range of extruded twinwall plastic sheet products produced from high impact polypropylene resin with a similar make up to corrugated fiberboard it is a light weight tough material which can.

0 46 mpa iso 75 c 78 heat deflection temp.

Item test method unit 2 mm 3 mm 4 mm 5 mm 6 mm 8 mm 10 mm 13 mm unit weight g m2 490 600 750 1000 1400 1800 2000 2500.

The materials used include polypropylene and polyethylene widely used and versatile thermoplastics.

13 x 10 5 oc 1 b water absorption at 24 hours immersion astm d 648.

1 82 mpa iso 75 c 52 vicat softening point 1 kg 10n iso 306 c 148 vicat softening point 5 kg 50n iso 306 c 78 pag.

0 02 c melting temperature dsc method.

Wvtr g cm2 x hr 8 3 x p1 p2 l where p1 and p2 are the partial pressures.

1 2 corrugated plastic sheet.